I can’t claim these are the best work I’ve done. There’s still a lot to learn.

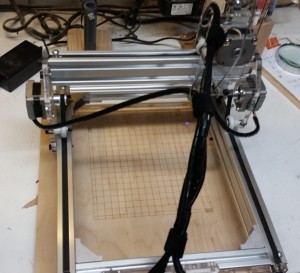

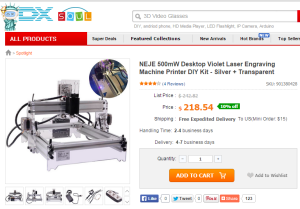

Creating content from scratch is pretty easy using Inkscape and the laserengraver extension from this instructables post. I should also note that I’m using a laptop running ubuntu and Universal G-code Sender to control the machine.

So, Like I said, straight vector based graphics are pretty easy to manage and come out quite well. But an awful lof of content you might want to play with are raster based. I’ve experimented with 2 methods of generating gcode from raster images.

The first is to use Gimp to edit the file and adjust the color levels to try and get an image that has only black and white in it. This can be easier said than done, and may require some manual clean up work. Once doing that, you can transfer the bitmap into Inkscape and use the ‘Trace Bitmap’ tool to convert that into a series of paths (? still learning inkscape and its terminology). That method can require quite a bit of clean up of the paths, depending on how good of a job at converting to black and white you did.

These two are examples of that method. The one on the left I might need to decrease the speed of the laser to burn a little deeper. The one on the right, you can see some speckles in it that I later cleaned up by removing the paths that made up those dots.

Another method is to use LaserEtch by JTech Photonics. You still need to convert an image to BW, and do some clean up. It then generates G-code that will etch the image by going back and forth and turning the laser on and off. This method will be very useful for creating PCB’s, but it’s can also be used to burn an image that you might not want to turn into vectors. Here’s a pic of a logo I threw together quickly for a great radio show you can hear on Thursday nights. It’s Zorch Radio on Real Punk Radio. Hell, Tune in to the entire Wrecking pit and listen to Gone Mental at 6:00pm and Zorch Radio at 7:00 till 10:00pm.

I think with a little manual edting of the file I can clear this up quite a bit. Took me 5 minutes to convert the image, and rendering probably took around 45 minutes for a 95mm x 20mm image.

Edit: Inverted the black and white and did a little cleanup to make the letters more separated. Turned out much better.

Ok, Maybe one complaint. At some point during the first day, the laser quit being able to shut off during use. It appears that the SMD mount transistor on the board that controls the laser went bad. In my attempt to replace it, I managed to screw up the board a bit, but finally just soldered some jumper wires in place and plugged in a replacement transistor I had laying around. Bada Bing, Bada boom, I’m back in business. It looks a little goofy, but it works fine now.

Ok, Maybe one complaint. At some point during the first day, the laser quit being able to shut off during use. It appears that the SMD mount transistor on the board that controls the laser went bad. In my attempt to replace it, I managed to screw up the board a bit, but finally just soldered some jumper wires in place and plugged in a replacement transistor I had laying around. Bada Bing, Bada boom, I’m back in business. It looks a little goofy, but it works fine now.